Our Machinery

Cleaning Machinery's

Rotary Drum Washer Machine

The machine is a drum structure made up of a cleaning drum, a main shaft, and a brush transmission device. When working, the transmission device rotates the drum and the main shaft, and the friction between the roller and the raw material, as well as the brush and the raw material, is utilized to remove mud and sand stuck to the raw material's surface. The raw material is moved from the feed port to the discharge port, allowing for continuous operation.

The machine has food-grade nylon brush cleaning, a high-pressure water rinser, material automated rotate discharging, easy disassembly and operation,

automatic separation of water and slag, and a high torque tooth wheel reducer.Application :

This equipment is useful for cleaning carrot, beetroot, ginger, beans,nuts,sweet potato, and so on. It can remove the tightly attached mud and sand on the surface and recess of the raw material while also being suited for the peeling of round fruits and vegetables after blanching and soaking.

Bubble Washer Machine

Machine Description :

The air bubble fruit washing machine is made up of two parts: a water bubbling tank and an elevator, which are used to clean fruits and vegetables such as tomatoes, carrots, ginger, cabbage, apple, orange, mango, and pineapple berries.The air bubble washing machine tank holds clean water, and the elevator transports clean fruits to the next station for sorting.The combination of an air blower and water creates a tumbling state to

remove agricultural residues from the surface of fruits and vegetables.To meet the aim of washing, floating debris can overflow from the overflow tank, and sediment is expelled from the sewage outlet. The elevator continuously pushes and elevates the raw fruits and vegetables.The elevator has a spray nozzle assembly to rinse the fruits and vegetables under high-pressure water once again.

Wet Hopper Machine

Our wet hoppers use an innovative combination of air and water to gently pre-wash the crops before they go through the washer or polisher. The hopper size can be chosen to Provide enough reserve to help regulate the flow of your washing line.

Brush Washer Machine

The Fruit Brush Cleaning / Washing Machine is suitable for cleaning round and elongated fruits and vegetables, waxing and polishing fruit surfaces, or peeling fruits and vegetables after hot soaking with lye. It provides a significant value for businesses in terms of labor savings, improved production efficiency, and cost reduction.

It is mostly used to clean, peel, and polish carrots, ginger, potatoes, peppers, medicinal materials, and other rhizomes and tubers. Applicable to fruit and vegetable cleaning machines in dehydrated vegetable factories,

rapid frozen food manufacturers, pickled vegetables, and canned processing plants.Application :

The equipment is mostly used to clean apples, mangoes, pineapples, pears, carrots, and other similar fruits and vegetables. This equipment is designed to meet the sanitary requirements of the food industry. It is simple to use and maintain, and it may be connected to automated production lines.

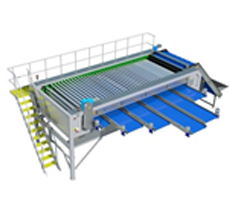

Roller Type Washer

Machine Description :

All contact parts are stainless steel, with a simple design and a robust structure. The material is continually fed into the hoper and washed by gentle tumbling movement. Suitable for peeling/cleaning/washing a

variety of vegetables such as radishes, carrots, potatoes, ginger, turnips, stem roots, and so on. The washer has a water spray jet system that washes/cleans the vegetables at the same time.The washer is composed of SS-304 and meets food sanitation standards. The washer has revolving soft/hard brushes that completely clean the vegetables while also peeling them. The washer's unique design allows the user to visually assess the level of wash/peel achieved. The cleaned vegetables are taken from the side exit outlet after they have been washed.